What You Need to Know About Spiral Steel Pipes: A Comprehensive Guide

- Share

- Issue Time

- Mar 14,2019

Summary

Welcome to our comprehensive guide on spiral steel pipes, where we delve deep into their manufacturing processes, applications, and advantages. As a leading provider in the industry, Cangzhou Spiral Steel Pipe Manufacturer is committed to providing you with detailed insights that will enhance your understanding of this critical infrastructure component.

What You Need to Know About Spiral Steel Pipes: A Comprehensive Guide

Welcome to our comprehensive guide on spiral steel pipes, where we delve deep into their manufacturing processes, applications, and advantages. As a leading provider in the industry, Cangzhou Spiral Steel Pipe Manufacturer is committed to providing you with detailed insights that will enhance your understanding of this critical infrastructure component.

Understanding Spiral Steel Pipes

Spiral steel pipes are essentially a form of welded steel pipe characterized by their unique production technique. Unlike traditional straight seam pipes, spiral pipes are created by spiraling a flat steel strip around a cylindrical form, resulting in a continuous weld along the length of the pipe. This method not only enhances the mechanical properties of the pipes but also allows for greater flexibility in pipe diameter and wall thickness.

The Manufacturing Process

The manufacturing of spiral steel pipes involves several intricate steps:

- Material Selection: High-quality steel strips are chosen based on the intended application and required specifications.

- Forming: The steel strip is heated and then formed into a spiral shape using specialized machinery.

- Welding: A continuous weld is applied along the seam of the spiral pipe, ensuring strength and integrity.

- Inspection: Rigorous quality control checks, including non-destructive testing, are conducted to ensure conformity to industry standards.

- Coating: Optional protective coatings can be applied to enhance corrosion resistance, depending on the intended use.

Applications of Spiral Steel Pipes

Spiral steel pipes are widely utilized across various sectors due to their versatility and structural integrity. Here are some key applications:

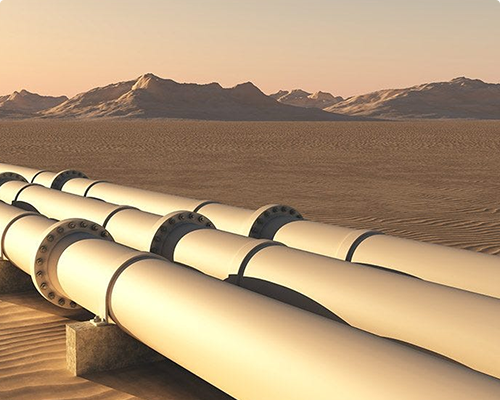

1. Oil and Gas Industry

In the oil and gas sector, spiral steel pipes are essential for transporting crude oil, natural gas, and other fluids over long distances. Their strength and durability make them an ideal choice for high-pressure applications.

2. Water Supply Systems

Municipalities rely on spiral steel pipes for water distribution networks. Their robust design ensures longevity and resistance to various environmental factors, making them a reliable choice for essential infrastructure.

3. Construction and Infrastructure

Spiral pipes are used in construction for piling applications, drainage systems, and structural support. Their ability to withstand heavy loads is crucial in urban development projects.

4. HVAC Applications

Heating, ventilation, and air conditioning systems benefit from the lightweight yet strong properties of spiral steel pipes, which are often used for ductwork and exhaust systems.

Advantages of Spiral Steel Pipes

The use of spiral steel pipes comes with numerous advantages that make them a preferred choice in many industries:

1. Enhanced Strength and Durability

Due to their spiral weld design, these pipes exhibit superior strength compared to conventional pipes. This makes them highly resistant to internal pressure and external forces.

2. Cost-effectiveness

Spiral steel pipes can be produced efficiently, reducing manufacturing costs. Additionally, their longevity translates to reduced maintenance and replacement expenses over time.

3. Flexibility in Design

The manufacturing process allows for customized diameters and wall thicknesses, catering to specific project requirements without extensive lead times.

4. Eco-friendly Options

With an increasing focus on sustainability, many manufacturers, including Cangzhou Spiral Steel Pipe Manufacturer, offer eco-friendly options that incorporate recycled materials and energy-efficient production methods.

Quality Standards and Certifications

At Cangzhou Spiral Steel Pipe Manufacturer, we adhere to strict international quality standards, including ISO 9001, API, and ASTM certifications. These certifications ensure that our products meet rigorous safety and performance criteria, providing our customers with peace of mind when selecting spiral steel pipes for their projects.

Conclusion

In conclusion, spiral steel pipes represent a vital component in numerous industrial applications. Their unique manufacturing process, combined with exceptional strength, versatility, and cost-effectiveness, positions them as a top choice for engineers and procurement professionals alike. For more information or to inquire about our range of spiral steel pipes, please contact Cangzhou Spiral Steel Pipe Manufacturer today. We are dedicated to delivering high-quality products that exceed your expectations.